Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

The Screwdriver Function Module (SFM) for automated production

- Wide product variety for all applications

- Maximum ease of integration

- Service optimized

- Suitable for a complete process documentation

- Standard modules allow for short delivery times

Screwdriver Function Modules are the basis of any automated, process-reliable screw-assembly. You benefit from our long-standing experience in the fields of screwdriving technology and assembly automation.

We offer both single-spindle and multi-spindle units.

Wide product variety for all applications

DEPRAG screwdriver function modules excel through their wide design variety. There is a solution for every application. For example, the screwdriver function modules are available for a large torque range in both single- and multi-spindle execution.

The modular design of our screwdriving units is based on 6 different standard designs:

- Standard execution

A slender design for horizontal or vertical screwdriving. - Short execution

For limited space access. - Underfloor execution

For a vertical, inverted assembly. - Vacuum execution

For difficult to access or recessed screw-locations in any assembly direction. - Pick & Place execution

For fasteners presented to a defined pick-position. - Nut execution

For the automatic feeding and assembly of nuts.

Maximum ease of integration

The compact, robust design and the simple connection ports allow the easy integration of our modules into your assembly system. Our screwdriver function module can be integrated into any machine and reduces your engineering efforts considerably. Your module is supplied as an integration ready fully functional component, which has been specifically and extensively tested with your sample parts.

Service optimized

The goal of our design engineers is the optimization of your service- and maintenance efforts.

Every DEPRAG screwdriver spindle is equipped with a quick-change-chuck that allows a fast bit exchange that takes only seconds.

Our screwdriver function modules are designed in such a way that standard bits and sockets can be used. This results into an extensive savings of follow-up costs and reduces downtimes.

It only takes a minute to exchange a screwdriver spindle to perform a calibration or maintenance: Simply loosen one nut!

Fast and simple bit exchange that takes only seconds

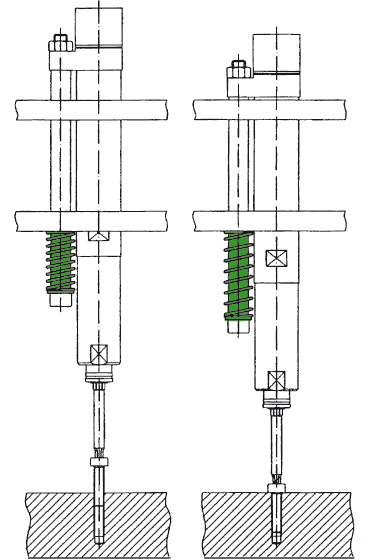

Axial spring load without the need for special bits

Multi Spindle Screwdrivers always require a stroke compensation. All of our screwdriver spindles are therefore equipped with a lateral guide bolt and spring to regulate the ”end load pressure” of each drive spindle. We do not use custom made and/or spring loaded bits or sockets. Internationally available and ”standard” bits and sockets are compatible.

Suitable for a complete process documentation of all screwdriving parameters

Our Screwdriver Function Modules can be equipped with any DEPRAG Screwdriver. When outfitted with an EC-screwdriving-system, the complete acquisition of the processing-data is possible. Besides the display of torque- and angle values, it is also possible to display the status of screw-depth and screw-reloading, which allows the next cycle.

Standard modules allow for short delivery times

Due to the modular design, the screwdriver function module can easily and individually be adapted to fit your application.

This is because of the use of many standard components. A high level of availability and short delivery times are the result.

Stroke variants of DEPRAG Screwdriver Function Modules:

Stroke variant A: Without Screwfeeding

If you have an application with pre-positioned screws (automatic screwfeeding is not necessary), then we equip your Screwdriver Function Module with only one actuating cylinder for the spindle stroke.

Stroke variant B: Automatic screw presenting through a defined pick-position

Does your application require the automatic presentation of a screw by a feed-system with a pick-position? Then we can offer a suitable Screwdriver Function Module that incorporates not only a spindle-stroke but also a pick-stroke for lifting the fastener from a pick-position.

Stroke variant C: Robotic application with automatic screwfeeding through a feedhose

Do you use a robotic module that carries out the feed-stroke and where the screw is presented by an automatic screwfeed system? For such an application, the Screwdriver Function Module is equipped with a mouthpiece, a guide sleeve (nosepiece) and only one actuating cylinder for the spindle-stroke.

Stroke variant D: Stationary use with automatic screwfeeding through a feedhose

For this application, the Screwdriver Function Module is structurally integration into your system. Mouthpiece and nosepiece have to be moved on top of the screw-location. Therefore, the Screwdriver Function Module is equipped with two actuating cylinders; one for the mouthpiece-stroke and one for the spindle-stroke.

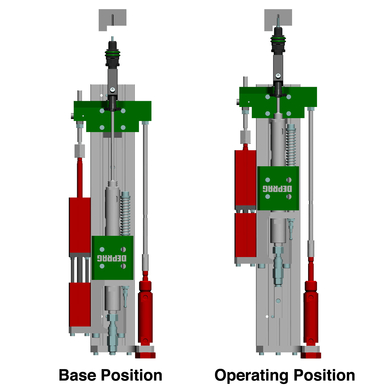

Stroke variant E: Underfloor (inverted) use with automatic screwfeeding through a feedhose

For vertical, inverted assemblies, a possible danger is that the screw fed into the nosepiece (guide-sleeve) drops back into the tooling because of the gravity. For those types of applications we equip the Screwdriver Function Module with an additional actuating cylinder: Besides the strokes for mouthpiece and spindle, and additional locking-stroke is applied to the forward-positioned bit to avoid the dropping-back of the screw. When compared to other offered systems, where the screw is being held in position by a continued air-pressure, our locking-stroke technology is especially process-reliable and efficient.

Stroke variant F: Customer specific design

Naturally, for all applications that cannot be handled by our standard products, we offer cost-effective, customer-specific solutions that are based on our standard modules.

Screwdriver Function Module SFM-L

Single-spindle execution

- Torque range: 0.02 Nm – 0.8 Nm

- Mouthpiece stroke: 25 mm, 80 mm, special stroke lengths are available on request

- Max. screw head diameter: up to 10-mm

Screwdriver Function Module SFM-N

Single-spindle execution

- Torque range: 0,06 Nm -20 Nm

- Mouthpiece stroke: 25 mm, 80 mm, special stroke lengths are available on request

- Max. screw head diameter: up to 14-mm

Screwdriver Function Module SFM-S

Robust multi-spindle design for the use of multiple screwdrivers and high thrust forces.

- Torque range: adapted to your application

- Mouthpiece stroke: 25 mm, 80 mm, special stroke lengths are available on request

- Max. screw head diameter: up to 14-mm