Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

This revolutionary tool is a true game changer for the industry!

Adaptive direct fastening of sheet metal:

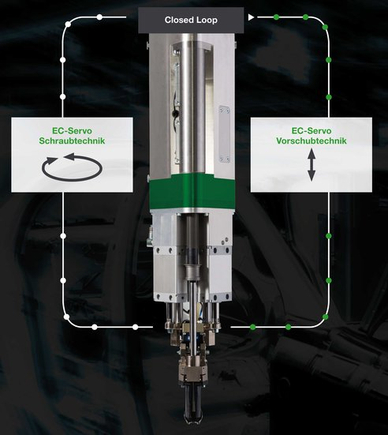

The adaptive assembly unit ADAPTIVE DFS combines EC-Servo screwdriving technology with EC-Servo stroke technology

ADAPTIVE DFS Video

Application

ADAPTIVE DFS

ADAPTIVE

The recognition of penetration is independent from tolerances in the fasteners and products. The process parameters will automatically adjust thus regarding in an optimized process.

Advantages:

- Highest process reliability

- Shortest possible cycle time

- Optimized funnel forming

- Avoids thread damages

- Less stress on fastener and product

- Reduces set-up time

- Designed for new materials, fasteners and joining methods

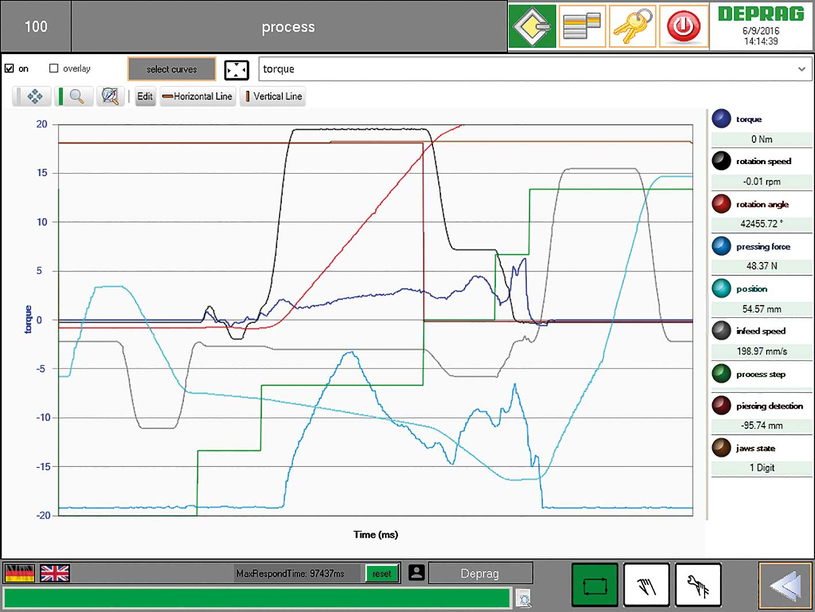

Precise and automatic recognition of penetration points

The constant data reported by the control modules enable the precise and automatic recognition of all relevant penetration points.

Optimal processing parameters, independently from the tolerances

Time-critical and essential parameter changes are autonomously performed by the fastening system. The system ensures the ideal processing parameter, independently from the tolerances of the product or fastener. It significantly reduces the effort of preliminary analysis and parameterization. Costly and extensive repair procedures that are caused by inaccurately formed holes, jammed screws or ruined threads are kept to a minimum.

The best possible processing-parameter that have been automatically adapted to suit any situation, guarantee that the parts to be connected (fastener and product), are subjected to the least amount of strain.

The additionally captured processing-data allow an increased process documentation.

Top flexibility during processing of multiple materials

Separate electronic controls for the EC-Servo screwdriver and the EC-Servo stroke technology, in combination with the extensive parameterization possibilities, ensures highest flexibility during the processing of multiple materials.

Prepared for new materials and fasteners

The implementation of special tightening sequences for new fasteners and materials is possible. Especially for the assembly of future material such as carbon-fiber and CFRP, the controlled feed stroke allows that exact positioning and trigger-points are clearly defined.

You can find detailed technical specifications on our ADAPTIVE DFS in the following catalog:

And service: